Advantages of Stepper Motor Over Dc Motor

A compound motor also needs frequent maintenance due to the aging of parts and its maintenance costs are relatively high. One way to accomplish.

Difference Between Stepper Motor And Servo Motor The Engineering Knowledge

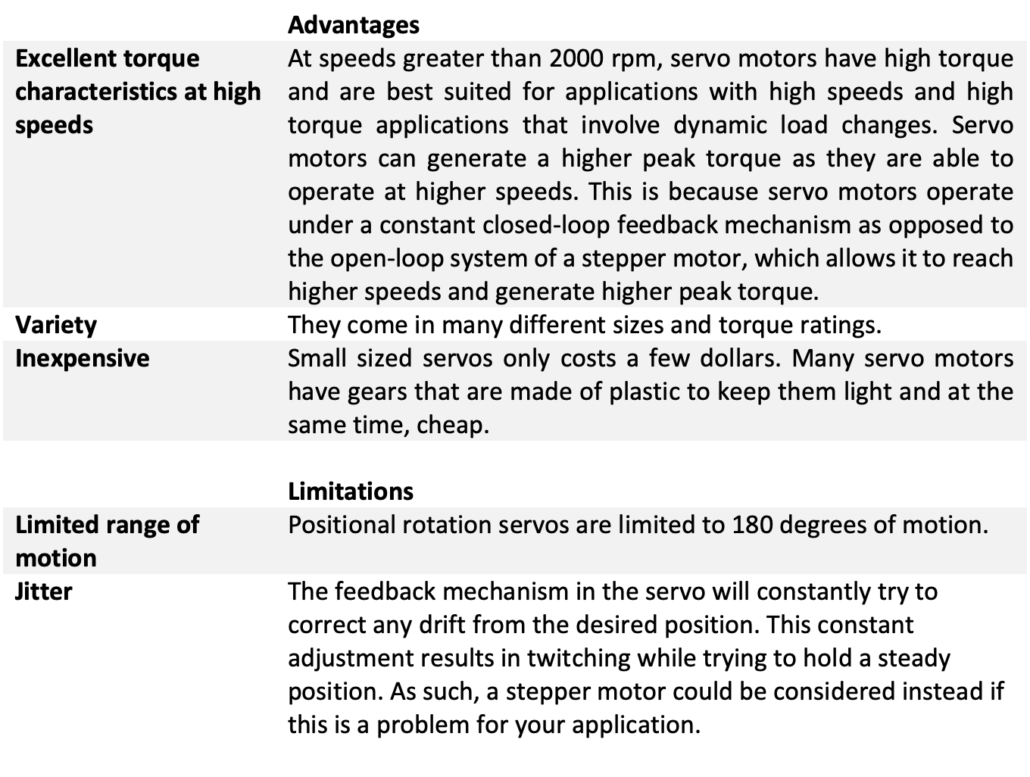

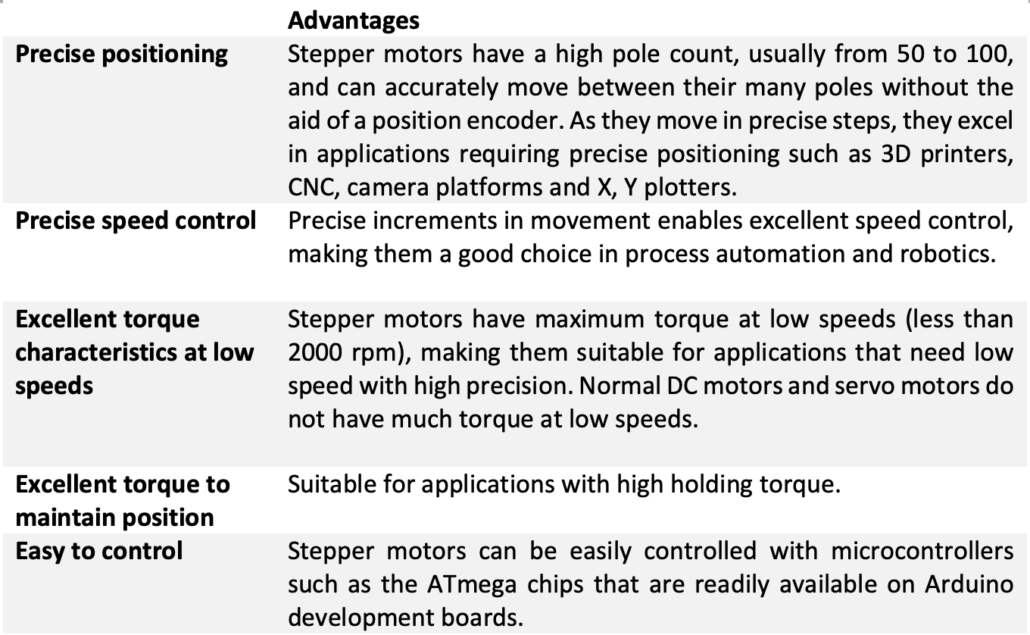

The performance of a stepper motor both in terms of resolution or step size speed and torque is influenced by construction details which at the same time may also affect how the motor can be controlled.

. The construction of a stepper motor is fairly related to a DC motor. It also offers smooth acceleration and deceleration operation. Quick Starting Stopping Reversing and Acceleration.

Construction of a Stepper Motor. Motions can be programmed with multiple stopping points. Speed control of DC series motor is done by the armature control and field control methods.

It includes a permanent magnet like Rotor which is in the middle it will turn once force acts on it. The stator is arranged near to rotor so that magnetic fields within the stators can control the movement of. Equipped with a motor offering excellent controllability our linear actuators offer the following advantages over hydraulic and pneumatic actuators.

Armature Resistance control method for DC series motor. However they increase the number of poles so the synchronous speed decreases to 72 RPM at 60 Hz. Another type of synchronous motor called the low-speed synchronous motor provides highly precise speed regulation low-speed rotation and quick bi-directional rotation.

The Brush DC motors consist of six different components. Stepper Motor Types and Construction. There are four main types of DC motor all of which are used for different applications.

18 09 or less. The P5000 is a compact micro-stepping stepper drive optimized for high system performance with Kollmorgens industry leading POWERMAX II. These motors are known for high torque to inertia ratio.

There are several types of stepper motors are available in todays market over a wide range of sizes step count constructions wiring gearing and other electrical characteristics. The circuit diagram of this method is as shown in the below figure. Speed Control of DC Series Motor.

Axle commutator armature stator magnets. The motors position can be commanded to move and hold at one of these steps without any position sensor for feedback an open-loop controller as long as the motor is correctly sized to the application in respect to torque and. Because there is usually no motor feedback a periodic position verification may also be used to confirm accurate movements for ongoing operation.

While this makes driving stepper motors more complex there is a major advantage over brushless DC motors. The brush DC motors have the ability to provide the torque three to four times greater than their rated torque. Due to the spark.

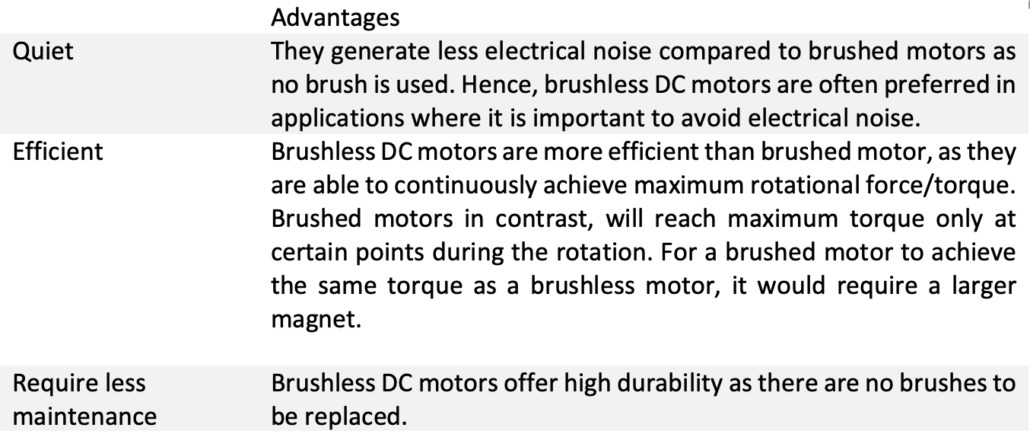

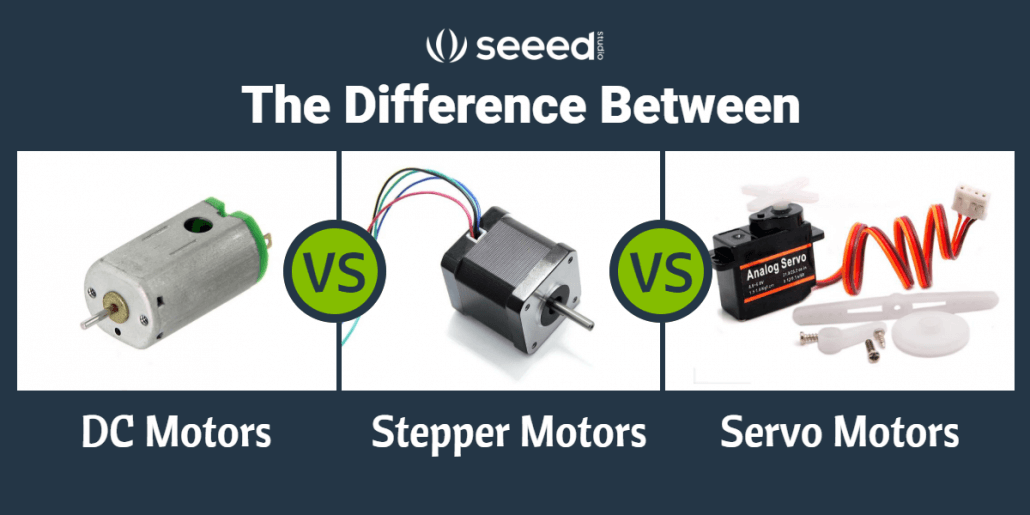

For instance they run quieter cooler and are more precise in operation than a brushed motor. The classification of motors can be done based on the type of supply like AC motors DC motors. BLDC motors and step motors have advantages over other electrical motors in certain applications.

For example if you want a motor to rotate exactly 270 degrees this would be near impossible to do with a general DC brushless motor without some form of feedback but would be a breeze. In this method a variable resistor or rheostat connected in series with armature resistor. Stepper systems can only perform accurate relative movements after the controller has learned the home position through a homing procedure.

The advantages of a brushless motor over brushed motors are high power-to-weight ratio high speed nearly instantaneous control of speed rpm and torque high efficiency and low maintenance. Homing and Position Verification. The actuator is very stable when operated even at low speeds.

A stepper motor also known as step motor or stepping motor is a brushless DC electric motor that divides a full rotation into a number of equal steps. If you want to know everything about a DC motor DC motor types and their utilizations. In a conventional DC motor the back EMF generated is given by mathrm𝐸_𝑏 𝑘φ𝑁.

As you may know a DC motor or a direct connection motor is referred to as any type of rotary electric motors that converts direct electrical energy into mechanical energy. DC Motor speed can be controlled by varying the supply voltage and is available in a wide range of voltages although the most common form is 12 24V with some of the advantages being. As these motors are capable to operate in discrete nature these are well suitable to interface with digital control devices like computers.

18 09 or less. Unlike brushed DC motors which have permanent magnets on the stator BLDC motors use permanent magnets on the rotor. Variable reluctance stepper motorVR Permanent magnet stepper motor PM Hybrid stepper motorHB Cost.

These motors use permanent magnets in the rotor so theyre very responsive. Of the stator which is wound through a magnetic coil all over it. As the field flux in a permanent magnet DC motor is produced by permanent magnets hence the field winding is not shown in the equivalent circuit.

Stepper drives for both AC and DC power applications are ideal for high-performance indexing applications offering microstepping capabilities up to 50000 steps per revolution with no need for feedback systems. There are several variations of the brushed DC motor but in robotics permanent magnet DC motors are used. The equivalent circuit of a PMDC motor is shown in Figure-2.

Brushless motors find applications in such places as computer peripherals disk drives printers hand-held power tools and vehicles ranging from model aircraft to. DC Motors are commonly used. Under these AC DC motors there are different kinds of motors comes as induction motor reluctance motor DC shunt PMDC stepper synchronous etc.

Compound motors indeed have many advantages over other motors nevertheless just like all other types of motors the compound motor has few disadvantages too which are been discussed and delivered briefly below. Their angular position can be specified with a great degree of accuracy. This rotor is enclosed through a no.

We know that the main function of a motor is to change the energy from one form to another like electrical to mechanical. As a matter of fact not all stepper motors have the same internal structure or construction as there are different rotor and. Speed control over a wide range.

Dc Motor Vs Stepper Motor Vs Servo Motor Which To Choose

Dc Motor Vs Stepper Motor Vs Servo Motor Which To Choose

No comments for "Advantages of Stepper Motor Over Dc Motor"

Post a Comment